Biomass Pellet Market in Lithuania

1. Abstract

There are different types of biomass in Lithuania including wood biomass, Straw and Perennial Grass bio fuel, Energetic Willow bio fuel and Municipal Waste biomass, the potential of renewable energy in Lithuania is huge. Also this study introduces the current pellet situation and pellet trade in Lithuania, the pellet quality and standard of Lithuania is European Standard.

2. Biomass Sources in Lithuania

Biomass is currently the most important form of renewable energy in Lithuania, and will remain so until 2020, and also beyond. The current use of biomass is mainly wood used for room heating. 80% is used for domestic heating while 6.6% is for heating in the service sectors, 6.4% for district heating, and the rest for industry and agriculture. Lithuania possesses enormous renewable energy sources that are being left to decompose without any benefit in forests, fields or communal waste dumping grounds. Here are some biomass resources in Lithuania.

Wood biomass

Wood fuel and wood waste fuel are the most widely used RES in Lithuania- up to 86 percent.

The wood cutting and forest cleaning residues accumulated in Lithuanian forests is one of the most promising kinds of local fuel. According to LITBIOMA, the forest cutting residue potential amounts to about 1 million m3 per year. Such resources allow an annual energy production of 2152GWh.

Presently, wood fuel energy is the most accessible RES for consumers. This could be due to the availability of supplies. Production of other RES in Lithuania is far less developed and the capacities are smaller.

Straw, Perennial Grass Bio fuel

About 2.4 million tons of straw are available every year in Lithuania but only a minor part is used for energy production. The economically reasonable straw potential amounts to 0.5 million tons which can lead to production of around 1500GWh of energy.

Energetic Willow bio fuel

According to calculations performed by LITBIOMA, until 2013 Lithuania could establish 11 500 energetic plantations in its 400 000 ha of unused, infertile land. The biomass produced by these plantations could allow an annual energy production of 500GWh.

Municipal Waste Bomass

Lithuania is among the few EU newcomers that are still polluting the environment with their municipal waste- leaving it to decompose on dumping grounds, instead of using it for energy production. At the moment there are more than 420 modern waste burning plants fitted for environmentally-friendly heat and energy production operating all around Europe. By burning municipal waste, the amount of which in Lithuania reaches 1.3 million tons every year, it would make it possible to produce around 30 percent of centrally supplied thermal energy. By using the municipal waste for energy production in modern power stations, its amount on the country’s dumping grounds could be reduced by up to five times.

3. Current Situation

Recently, the Lithuanian electricity system is dominated by nuclear power production. Nuclear power share in electricity generation in 2009 accounted for 71%. However, at the end of 2009, main source of Lithuanian’s electricity in the Ignalina Nuclear Power Plant was closed and Lithuania has been facing difficult choices about where to find new sources of electricity. Hydro power is the dominating source of renewable electricity generation in Lithuania. In 2009 70% of green energy was generated by hydro power plants while wind farms generated 20% and bio fuel 10% separately. According to Lithuanian National Energy Strategy, the main emphasis of the renewable energy development will be on biomass. Lithuania had increased biomass-based electricity production from 100GWh/yr in 2009 to 1,200GWh/yr in 2020. In Lithuania, production of wood pellets started since 1999.

Lithuania has planned to significantly increase pellets production in the next 10 years. By 2020 biomass is targeted to cover up to 70% of heat energy and 6% of electricity. In 2008, production capacity of pellets reached 120 thousand tons per year. About almost all pellets are exported abroad. The annual volume of tree felling in Lithuania is around 6 million cubic meters. The consumption of wood fuel and wood waste fuel is around 3.7 million cubic meters. Wood accounts for 6 percent of the total energy produced in Lithuania. It is estimated that 1.5 million tones of biomass could be extracted from forest resources. The largest potential for forest fuel resources is located in the southeastern portion of the country.

Lithuania currently has four plants in full operation and total production stands at 150,000 metric tons per year, with 5,000-6,000 of those metric tons used within the domestic market, according to the Lithuanian Biomass Energy Association. As for exports, pellets are being shipped to Germany, Italy, Denmark and Sweden.

3.1.Biomass pellet trade

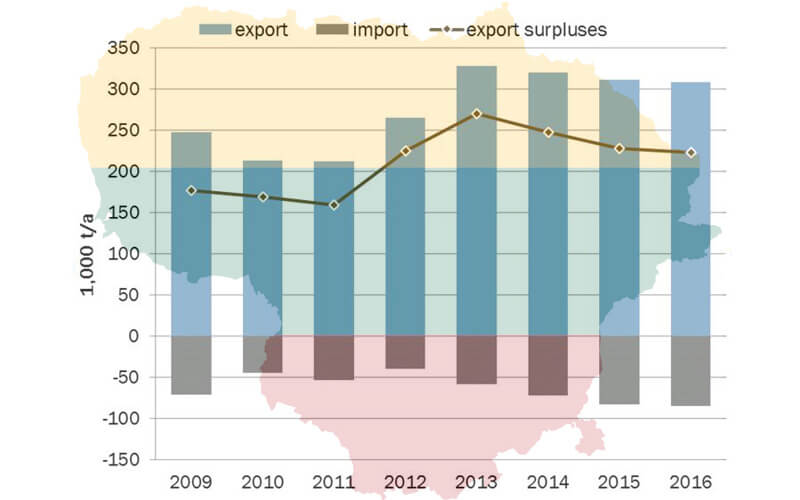

Today pellet market in Lithuania is still strongly export oriented. At the following figures is present pellet export from Baltic countries in 2010.

Major export directions of biomass pellets are Denmark, Italy and Latvia. According to Eurostat in 2010 the only import from Belarus to Lithuania was around 24,000 tones.

The major export flows from Eastern Europe originate from Russia and the Baltic States. Majority pellet exports to Europe take place through St. Peters burg harbor in North-west and via Riga harbor in Latvia. The remainder are transported by truck. T e prices of pellets exported from St Peters burg to Scandinavia and Western European countries were early 2010 at a level between €105 and €115 per tonne FOB. Average export prices in Riga have gone up on a annual basis to about 119€ per ton by the end of 2009, the average shipping costs from Riga to Denmark, as estimated by involved pellet actors, were about 20€ per ton. According to official data for 2012 December in Lithuania, the wood chips is 150€/toe, the straw pellets is 290€/toe.

3.2.Pellets quality and standard

There is no special wood pellet standard in Lithuania. Considering the fact that,major part of Lithuania pellet is exporting to Denmark and Italy therefore it is possible to assume that Lithuania producers using those countries pellet standards.

From January 2010 EN-plus(for private pellets) and EN-B(for industrial pellets) were introduced,consequently producers start manufacture pellet products in accordance with this new pan-European standard.

A feature of the new wood pellet standard EN 14961-2, which the EN-plus system is based on, is that there will be three different wood pellet qualities in the future. The A1 quality class is comparable to the former ÖNORM M7135 for wood pellets. Wood pellets of the A2 quality class are allowed to have a higher ash content of up to 1.5%. This can be the case especially with wood pellets made from deciduous wood. The quality class B denotes wood pellets with a higher ash content of up to 3.5%. These usually have a higher amount of bark and are not suitable for small furnaces. Larger heating plants, however, can burn these wood pellets without any problems.

This figure provides an overview of the most important pellet properties and their threshold values.

Leave A Comment