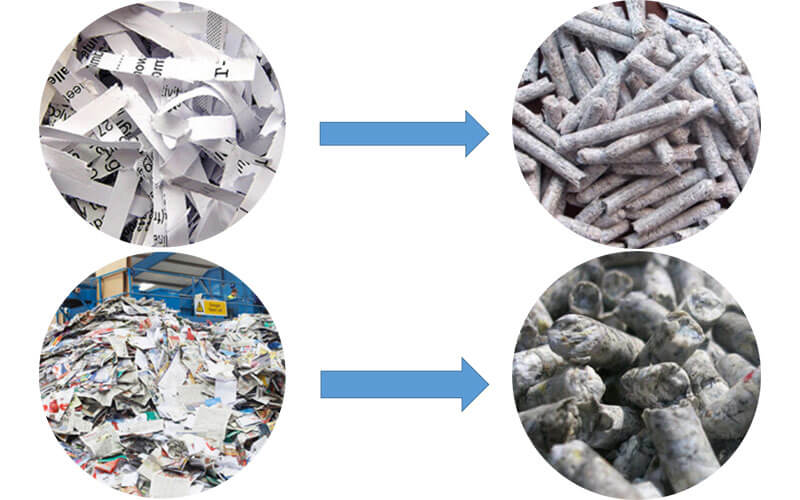

Make Paper Factory Residue into Fuel Pellets

1. The High Potential of Paper Factory Residues

1.1 Paper Factory Description

Paper is made from raw materials containing cellulose fibers, generally wood, recycled paper, and agricultural residues. In developing countries, about 60% of cellulose fibers originate from non-wood raw materials, including bagasse, cereal straw, bamboo, reeds, esparto grass, jute, flax, and sisal. The main steps in paper production are raw material preparation, like wood debarking and chip making; pulp manufacturing; pulp bleaching; paper manufacturing; and fiber recycling. In the paper factory, the generation of residues is unavoidable. Pulp and paper manufacturing is characterized by different cycles, both internal and external, and respects the hierarchy of reusing, recycling and what can not be recycled any longer is sent to energy recovery such as wood residues, bark residues, etc.

1.2 Different Types of Residues Generated in Different Paper Production Process Phases

1.2.1 Raw Material Preparation

The wood raw material used by the paper factory mainly comes from forests or by-products from the sawmill industry. Logging residues are mainly left in forests.

1.2.2 Pulp Manufacturing

Wood used for pulping is first debarked, leaving amount of bark residues. There are mainly two types of pulping method, namely kraft pulping(the dominant chemical pulping method) and mechanical pulping. Different pulping processes generate different residues.

In kraft pulping, wood chips are cooked with chemicals. Cooking removes lignin breaking up the wood into fibers. The residues from chemical pulping are green liquor dregs, lime mud, and lime sludge.

In mechanical pulping fibers are separated from each other either by grinding logs against a rotating stone or by refining woodchips between a rotating disc and a fixed plate. The residues from mechanical pulping are mainly a mixture of fibers and bigger wood components.

1.2.3 Paper Manufacturing

Residues from paper production include wood fibers and minerals.

1.3 Main Utilization of Paper Industry Residues

Here we take the European paper industries as an example.

From the chart we can see that paper mill residues are mainly used inside paper mills to satisfy the electricity and heat needs of the processes; but there are still many pulp and paper production residues which might otherwise be valuable for energy recovery, are put into landfills.

1.4 Energy Production

From paragraph 1.2 we can get the information that the majority of paper industry residues originate from wood, a natural resource, and so they can be used as biofuel for energy production. Combustion of these biofuel results in ash. However, if these residues are combusted as fuel directly, there are many disadvantages. They are irregular in shape, low in energy density, are generally affected by temperature and moisture, and can be difficult to transport. If they are to be used as common fuel, they should have the main characteristics of a common fuel, which can be achieved through densification. Densification creates a regular shape, increases energy density, reduces the effects of temperature and moisture, and increases ease of transportation. Making fuel pellets is an ideal method of densification of these paper mill residues.

2. Advantages of Making Fuel Pellets from Paper Mill Residues

2.1 Benefits of Fuel Pellets

Fuel pellets are more uniform in shape, size, energy content, and moisture than the paper mill residues, making them easier to transport, store, and convey when compared to other wood fuels and they need smaller storage space. Their high energy density means they have more energy by volume than paper mill residues.

In addition to these advantages of fuel pellets, the equipment to combust pellets is more automated and more efficiently then other biomass-fueled systems.

2.2 Benefits for Paper Factories

Worldwide, the pulp and paper industry is the fifth largest consumer of energy, accounting for four percent of the entire world’s energy use. Around 20% of the manufacturing costs of paper are energy costs. Thus it is crucial for paper factory to reduce the energy cost by finding a new clean and cheap fuel to substitute expensive fossil fuels. Fuel pellet is the one. One ton of wood pellets has the energy equivalent of 120 gallons of heating oil. By producing densified fuel pellets at the mill from mill residues and other waste wood to produce steam and electricity for papermaking, the paper factory can reduce coal use to a certain percent and thus reduce energy cost

Let’s take Flambeau River Papers as an example.

(This picture shows the aerial view of Flambeau River Papers with the wood pellet plant circled, lower center)

Flambeau River Papers located in Wisconsin, is a paper mill that has shifted to wood pellet fuel to reduce energy costs, which rescued the paper mill from bankruptcy due to rising natural gas and coal costs. An affiliate of Flambeau River Papers began producing densified fuel pellets at the mill from sawmill residues and other waste wood and pellets were used to produce steam and electricity for papermaking. When fully operational producing 13 tons of pellets daily, the Densified Fuel LLC affiliate would reduce coal use to about 10 percent.

2.3 Benefits for Environment

Fuel pellets are considered carbon neutral, meaning that the amount of carbon dioxide released when burning pellets are consumed is the same as carbon dioxide consumed from the atmosphere while a tree grows in the forest. So fuel pellets reduce pollution to the air in a large extent. It is a sustainable and environmental-friendly to dispose paper factory residues.

3. Fuel Pellets Production

3.1 Equipment for Making Fuel Pellets From Paper Mill Residues

The basic equipment includes:

Wood Hammer Mill: to crush large size paper mill residues into powder with the size of less than 6mm.

Sawdust Dryer: to lower the moisture content and make the materials suitable for direct pelletizing.

Wood Pellet Machine: the core equipment in the wood pellet production line. Pellet machine can be classified into flat die pellet mill and ring die pellet mill. Flat die pellet mill is suitable for small and medium wood pellet plant while ring die pellet mill is suitable for large scale wood pellet plant.

Fuel Pellets Cooler: to cool the hot pellets to the temperature similar to room temperature.

Pellets Sieve: to remove the residual fines in the pellets.

Biopellets Packaging Machine: weight and package the pellets automatically, especially for large scale pellet production line.

3.2 Technology of Pellets Manufacturing

3.2.1 Collecting residues

The collected biomass is usually of different size and so it has to be sorted and prepared for further process of pellet production.

3.2.2 Grinding

The large biomass materials should be reduced to the size of less than 6mm by wood hammer mill.

3.2.3 Drying

The moisture content of the material for producing fuel pellets is about 12%-15%. Drying of the powdery material can be carried out by rotary dryer or pipeline dryer.

3.2.4 Pelleting

The materials with the proper size and moisture content are fed into the wood pellet machine to make fuel pellets. There are two kinds of wood pellet machine, namely ring die wood pellet machine and flat die wood pellet machine.

3.2.5 Cooling

The temperature of pellets after compression is very high, about 90℃, so that cooling is an essential step in pellet manufacturing. By cooling, pellets are stabilized, hardened and finally shaped.

3.2.6 Sieving

Pellets are sieved to remove the residual fines. Fines are harmful in use and they are generally reused in the process and re-pelletized.

3.2.7 Packaging and storage

Pellets are packaged automatically by the biopellets packaging machine in bags. Because pellets are highly prone to moisture, it is very important to provide enough storage of finished pellets. Pellets also can be stored in the closed silos.

3.3 Cost Associated with Setting up a Pellet Plant

3.3.1 The basic costs for setting up a pellet mill are:

Raw material: 43%

Drying machine: 35%

Pelletizing machine: 7%

Personnel: 6%

Storage facilities: 3%

Peripheral equipment: 2.5%

Grinding equipment: 2%

General investments: 1%

Cooling equipment: 0.5%

When the availability of free material from a paper mill is considered, this cost array changes dramatically, with drying equipment consuming 93% of the set-up costs. This improves the importance of the feedstock price. Purchasing the biomass feedstock is the most costly aspect of pellet production. Drying the raw materials is the most energy-intensive aspect of pellet production.Therefore, due to large quantities of residues which are suitable for producing fuel pellets, it is beneficial for paper mills to make fuel pellets.

|

|

3.3.2 Pelleting Cost Versus Pellet Plant Size

Generally speaking, the cost and the pellet plant size are in the direct ratio.

4. Conclusion

In the aim of reducing energy cost and protecting the environment, it is a trend for paper mills to dispose their paper production residues in a sustainable, efficient and environmental-friendly way. Making fuel pellets from paper factory residues is a proven and efficient method.

Leave A Comment