Introduction of EFB Biomass

Empty Fruit Bunch (EFB) is the bio-mass of palm oil milling process, this biomass material can be used for energy generation, composting, mulching, pelletizing, etc. As the biomass pellet market booming these years, to convert the EFB into biomass pellets have been get the nod by the oil plant owners and the pellet market.

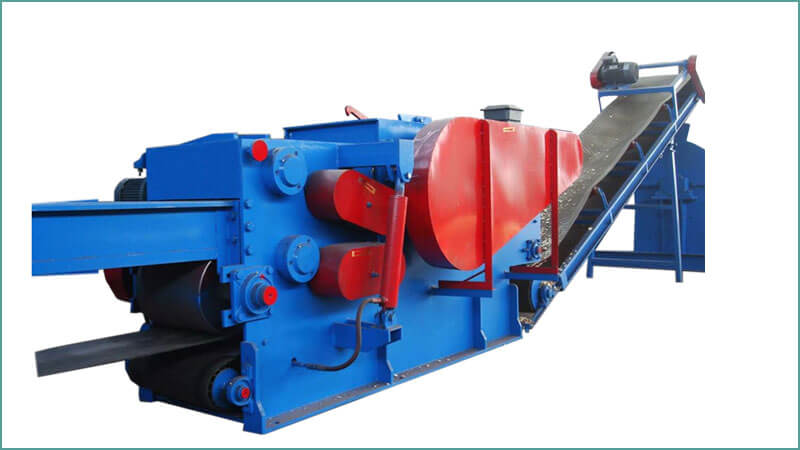

EFB Shredder

EFB shredder is an equipment to process palm fruit or coconut shell into palm fiber. It is one key machine of EFB pellet plant and can directly crush the fresh EFB into 10~30mm length fiber. The output fiber could be easily dried and fine crushed in the following EFB pellet processing, which guarantees the high quality of the final EFB pellets products.

EFB Shredder Features

1. Easy Installation

The shredder can be simply installed on the hardened and flat floor without any foundation to civil work, which can save the installation cost and move the machine conveniently.

2. Widen Feed Inlet

With the widened feed inlet, the EFB can be fed to the chopping chamber smoothly without blocking and intertwining.

3. High Production Efficiency

With unique designing of the roller and the knife inside of the machine, the lengthened roller, enlarged diameter of the roller and the unique arrangement of the knife, the machine can shred the EFB from massive to short fiber efficiently.

4. Long Serve Life

The machine shell is made from thick and heavy casting carbon steel, which is very strong and bear the running of the machine. We produce the knives and rollers with alloy steel and unique designing, which can shred the EFB efficiently and durably.

Empty Fruit Bunch (EFB) Shredder Working Video

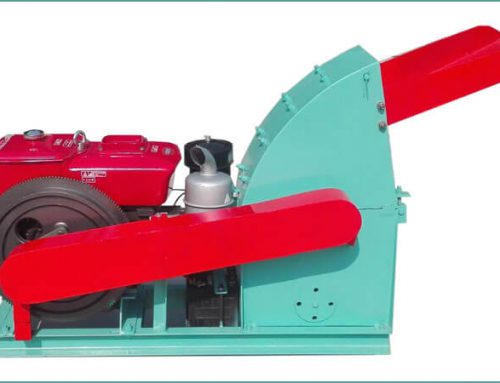

Introduction of EFB Fiber Crushing Machine

Hammer Mill Crusher is a machine to shredder the EFB fiber again into 4~10mm length. It is also a professional pulverizer to process lumber trims, slabs, veneer trims, edgings, blocks, oversized chips and solid wood. The pulverizing room is designed to be wide to crush material. Well balanced rotor makes the running very stable.

EFB Fiber Hammer Mill Features

1.Large opening for flexibility

2.Wide crushing room,high efficiency

3.Easy access and maintenance

4.Fully lined crushing chamber for longevity

5.Safe to operate, low noise, stable working.

EFB Fiber Hammer Mill Working Principle

• Material is fed into the mill’s chamber through the feed chute, typically by gravity.

• The material is struck by ganged hammers (generally rectangular pieces of hardened steel) which are attached to a shaft that rotates at high speed inside the mill’s grinding chamber.

• The material is crushed or shattered by a combination of repeated hammer impacts, collisions with the walls of the grinding chamber, and particle on particle impacts.

• Perforated metal screens or bar grates covering the discharge opening of the mill retain coarse material for further grinding, while allowing properly sized materials to pass as finished product.

| EFB processed by shredder | EFB fiber processed by crusher | ||

|

|

|

|

|

Model

|

AZS-CF1000

|

AZS-CF1500

|

|

Power

|

90kw

|

160kw

|

|

Capacity

|

2~4 t/h

|

4~6 t/h

|

|

Overall size

|

2500*1600

*1700mm |

3300*2100

*1900mm |

|

weight

|

2800kg

|

5500kg

|

|

Speed of main shaft

|

1400~1600

rpm |

1200~1400

rpm |

|

Number of hammers

|

72

|

120

|

|

Cutting size

|

4~10mm

|

5~12mm

|

EFB Shredder Technical Data

|

Model

|

Power

|

Capacity

|

Overall size

|

Numbers of knives

|

Weight

|

Size of Feed Inlet

|

|

AZS-G313D

|

22kw

|

1~3 t/h

|

2500*1700*1400mm

|

6

|

3100kg

|

300*280mm

|

|

AZS-G315D

|

37kw

|

3~5 t/h

|

2600*1800*1500mm

|

6

|

3500kg

|

480*200mm

|

|

AZS-G316D

|

75kw

|

10 t/h

|

2800*2500*1600mm

|

6

|

4500kg

|

900*250mm

|

|

AZS-G318D

|

110kw

|

12~15 t/h

|

3500*2400*1900mm

|

6

|

8200kg

|

750*300mm

|

Leave A Comment