Introduction to Diesel-driven Wood Hammer Mill

In bio pellets production, there are many important pre-treatment and after-treatment steps for best quality wood pellets. There are many sorts of wood grinding machines, one is wood hammer mill, others are wood crusher or wood chipper. What makes them different is the grinding part. As it’s name states, the main tools in wood hammer mill are hammers. Large wood particles fall into wood chamber and are crushed by hammers on rotating rotor. The material are impacted by the hammer bars and is thereby shredded and expelled through screens in the run of a selected size.

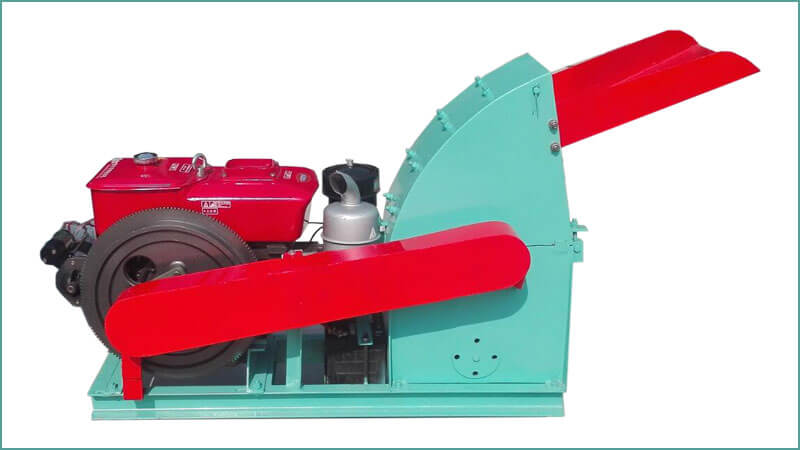

How Diesel Wood Hammer Mill Works?

Diesel wood hammer mill consists of feeding hopper, crushing chamber and delivery device. The key parts of diesel wood hammer mill is inner roasting rotors fixed with hammers. Started by diesel engine, diesel wood hammer mill runs in a high speed. Wood branches are swallowed and crushed by rotating hammers. With continuous hitting force from hammers, wood branches break into small wood particles until small enough to pass screen holes. Large particles need to be re-crushed for a better grinding. We also provide electric wood hammer mill for choice

Diesel wood hammer mill consists of feeding hopper, crushing chamber and delivery device. The key parts of diesel wood hammer mill is inner roasting rotors fixed with hammers. Started by diesel engine, diesel wood hammer mill runs in a high speed. Wood branches are swallowed and crushed by rotating hammers. With continuous hitting force from hammers, wood branches break into small wood particles until small enough to pass screen holes. Large particles need to be re-crushed for a better grinding. We also provide electric wood hammer mill for choice

Features and Advantages of Diesel Wood Hammer Mill

1. Diesel engine biomass hammer mill is suitable for areas short of electricity or areas inconvenient to connect electricity.

2. Mesh size can be adjusted from 2-10mm.

3. Suitable for small scale wood pellet production.

4. Easy to operate and maintain, stable working performance.

|

CF500A Diesel wood hammer mill

|

CF420A Diesel wood hammer mill

|

Safety Caution

1. Never put your hands into the hopper.

2. Wet wood branches need drying before being crushed. Proper moisture is 8% – 15%

3. The dimension of wood should be less than the inlet size.

4. Hammers need to be changed after long working period.

5. Daily maintain and cleaning are needed.

Diesel-driven Wood Hammer Mill Parameters

|

Model

|

CF420A

|

CF500A

|

|

Power

|

15HP

|

55HP

|

|

Capacity(kg/h)

|

200-500

|

800-1100

|

|

Screen Dimension(mm)

|

680*280

|

820*390

|

|

Cross Dimension(cm)

|

147*73*109

|

152*142*123

|

What Makes Our Diesel Wood Hammer Mill Different?

1. Diesel Engine

The outstanding features of our wood hammer mill is the diesel engine. Electric wood hammer mills are driven by electricity which would make wood pellets production unavailable in rural countries short of electricity. If there is not available electricity or the price of diesel is much lower than electricity, our diesel wood hammer mill is your best and first choice!

2. Various Capacities

The capacity of diesel wood hammer mill can be designed according to your demand. One thing we have to figure out is that though the capacity we stated is just a range because different raw material has different compression ratio.

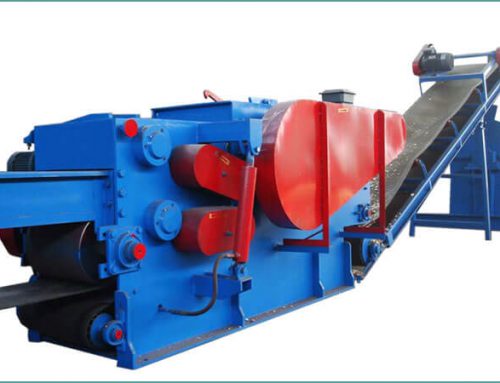

3. Dust-collecting Device

As small and light, wood particles processed by diesel wood hammer mill usually be blowed everywhere. Floating dust in air is harmful to human and for workers beside it’s better to build a clean and healthy working environment. Cyclone is one special collecting device which can collect processed small wood particles and reduce dust leaking. Cyclonic separation is a method to remove wood particles from air steam though vortex separation without filters. In wood chips and sawdust collection, rotational effects and gravity are main ways to separate the mixed air flow.

Leave A Comment